Managment System Certification

Managment System Certification

Product Certification

Certificate Search Certificate Search

| Name: | API |

| Reference: | 7-1-1077 |

| Issued By: | American Petroleum Institute |

| Validity Period: | 2014-03-19 ~ 2017-03-19 |

| Range: | PDC Bits |

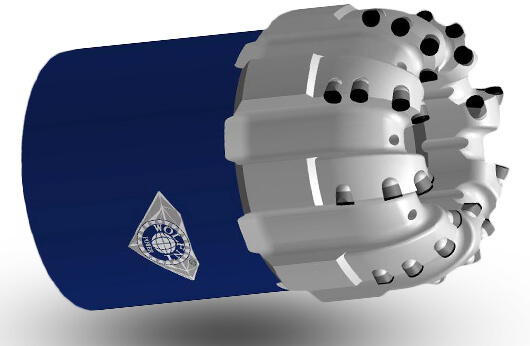

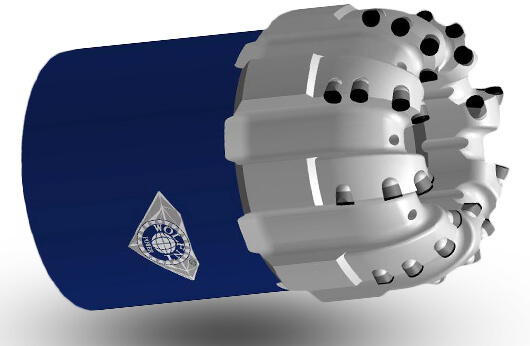

Core drill bits for hard rock

1.balanced force design

2.reasonable layout of PDC cutters

4.high speed

5.adequate stocks

Characteristics of diamond core drill bits for hard rock :

-Arc

type crown design and blade type cutter layout result in high ROP, high

core recovery reate and long working life of bit, etc.

-Use both PDC cutters and diamonds for gage protection for extended bit life.

-Dynamic

flow simulation technology is employed to optimize hydraulic design of

the bit and enhance the bit’s cleaning and cooling abilities.

-Inner

and outer diamond gage protection. The water course is located at inner

gage protection and consequently, cutting elements can receive

sufficient cooling and cleaning.

-Force-balance technology is used to improve stability of the bit and prevent the bit from balling up.

Diamond core drill bits for hard rock with matrix or steel body

Our

PDC core bits are the most cost effective way to drill or a core

sample. Our bits have 9 or 12 PDC cutters standard. The bits can be

constructed from matrix body or steel body. The matrix body bit will

last longer initially but can crack after substantial use. The steel

body bit is can be repaired and retipped at a considerable cost savings compared to purchasing a new bit.

These Diamond Bits use polycrystalline diamond (PDC) cutters to shear rock with a continuous scraping motion

1

Cutting structure is force balanced and bit blade is asymmetrically

designed so that the coal on bit is balanced that resulting better

stability of the bit.

2 Main cutters are high performance PDC cutters to insure service life of the bit while improving ROP

3 Cutter exposure is optimized to insure the bit can achieve higher ROP is soft to medium formations

4 Shock absorbers are designed to make the bit capable of drilling through formations with hard stringers.

5

Hydraulic system of the bit is optimized using dynamic flow palters

simulation technology to enhance cleaning and cooling effects of the bit

to effectively prevent bit from balling.

1.Matrix Body diamond core drill bits for hard rock |

Type and Features | PDC core bit can be customized for oil well,water well, mining, explorer well drilling. |

Suitable Formation | Various of hardness rocks or mud except the hardest hardness or ununiform rocks like cobble. |

Main Type | 75/54mm,94/74mm,113/89mm,113/109mm,153/129mm,215/105mm,etc. |

2.Steel Body diamond core drill bits for hard rock |

Type and Features | PDC core bit can be customized for oil well,water well, mining, explorer well drilling. |

Suitable Formation | Various of hardness rocks or mud except the hardest hardness or ununiform rocks like cobble. |

Main Type | 75/54mm,94/74mm,113/89mm,113/109mm,153/129mm,215/105mm,etc. |

Specifications of diamond core drill bits for hard rock |

Outside guage | 6 in 6 1/4 in 5 3/4 in | 152.4 mm 158.8 mm 146.1 mm |

Core diameter | 2 3/4 in | 69.9 mm |

Cutter size | 0.5”/16 (in pcs.) 0.39”/2 (in/pcs.) | 13/16 (mm/pcs) |

Total PDC cutters | 18pcs | 18 pcs |

Non changeable Nozzles | 6/0.39” (pcs/in) | 6/10 (pcs/mm) |

Height | 8.5 in | 215.9 mm |

Drilling Parameters of diamond core drill bits for hard rock |

RPM | 60-120 | 60-120 |

Weight on bit | 4000-12000 lbs | 2-6 tons |

Flow rate | 17-32 cfm | 8-6 L/sec |

Rotator Type | RSS, Motor | RSS, Motor |

WDT

6 blade diamond core drill bits are designed to be the primier drilling

bit with the greatest amount of core recovery in soft interbedded with

medium formations of 2-5 category of hardness.

These

bits are distinguished by an increased core recovery rate as they cut

through the formation smoothly & focus a consolidated core sample

through the centre of the barrel.

WDT

core bits are equiped with stabilizing inserts and cutters of increased

abrasive and wear resistance. These core heads are designed to track

symmetrically and produce straight non-deviating holes & cores.

29 core bits WDT style matrix or steel body

A - 5.50” X 9 cutter

B - 5.750” X 12 cutter

C - 6.125” X 12 cutter

Return PDC coring drill bit

Return PDC coring drill bit

Return Leading Products

Return Leading Products

In China

In China high-quality wear-

high-quality wear- Value,Crafts,

Value,Crafts, Win-win cooperation

Win-win cooperation Platform business

Platform business

Managment System Certification

Managment System Certification

Certificate Search

Certificate Search

Certificate Search

Certificate Search